In the precise processes of semiconductor manufacturing,each step requires the utmost accuracy and reliability.Particularly in the critical step of chip flipping,the use of high-performance brushless hollow cup motors such as the EC1630 in combination with encoders ensures that chips can be flipped quickly and accurately,thereby significantly improving production efficiency and product quality.

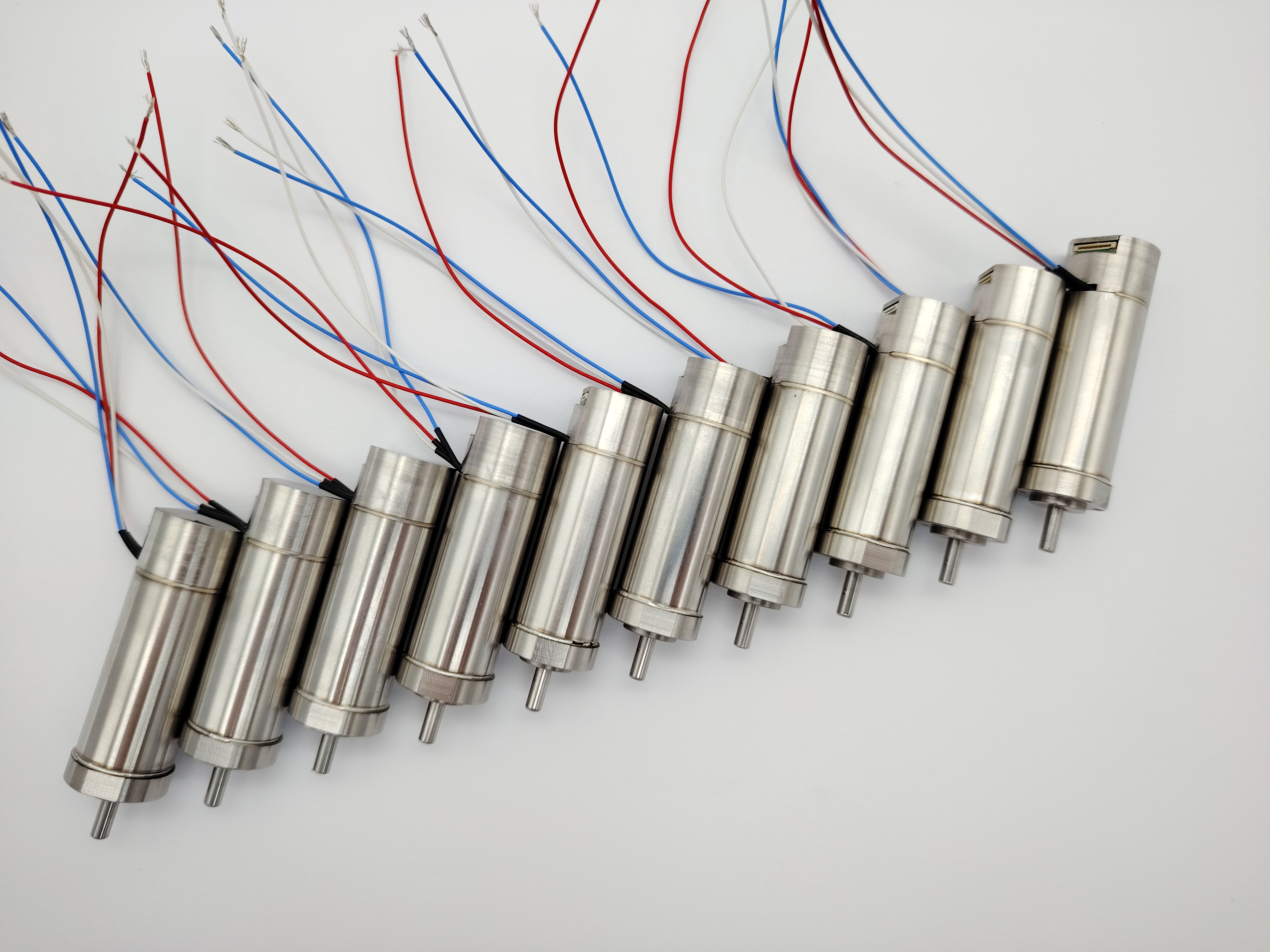

Highlights of the Brushless Hollow Cup Motor EC1630:

Compact Size:With a diameter of only 16mm and a length of 48mm,it integrates seamlessly into various precision devices.

High-Speed Response:Rated speed of up to 14,362 rpm(±5%),delivering rapid power output.Additionally,it provides strong torque to ensure stable operation even under high loads.

Precise Positioning:Combined with a high-precision encoder,it achieves accurate flipping and positioning of chips.

By integrating the EC1630 motor and encoder into the end-effectors of the equipment,not only is the necessary power provided,but also the optimal dynamic performance during the chip flipping process is ensured.This high-precision solution guarantees accurate handling of the chips throughout the production line,thus ensuring the high quality of semiconductor products.

Copyright © 2014-2025 LorentzDM Main Products: Micro DC motor、Micro Planetary Gearbox、Motor Encoder、Motor Driver、Drive System、Motor Brake